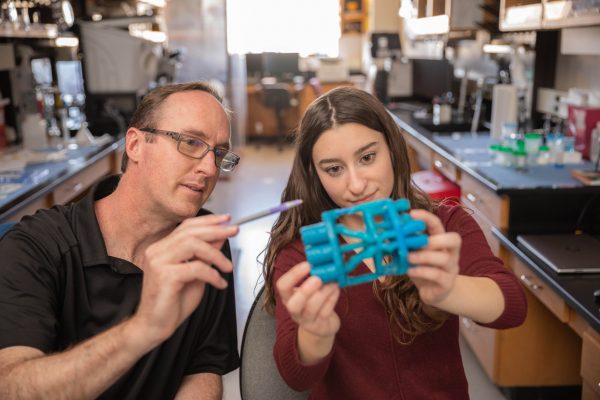

3D printer system

Our polymer 3D printing service utilizes cutting-edge technology to deliver high-quality, precision-printed parts for a variety of applications. Using the Stratasys Object 260 Connex 3 PolyJet printer, we can print multi-material prototypes, vessel models, and final components using the same materials as the digital anatomy J750/850 Stratasys printers, but at much lower cost – offering unmatched versatility and quality in polymer additive manufacturing.

Key features

- Innovative materials: We utilize UV-cured 3D printable acrylic-based copolymers from VeroClear (hard) and Agilus30 (Soft and flexible), or any combination in-between

- Biomedical focus: With a focus on the biomedical industry, we specialize in manufacturing physiologically matched tissue, heart (i.e LAA), and vasculature models (i.e circle of Willis) for in-vitro testing, providing invaluable tools for medical research and development.

- Print size: our printing capabilities range from a maximum print size of 10 x 10 x 8 inches, down to 16 µm resolution, allowing for the production of interconnected, complex, and detailed parts.

- Customizable solutions: whether you require intricate anatomical models or precise functional prototypes, our team has the expertise and technology to model and print virtually anything to meet your specific needs.

Compatible software usage (latest versions available)

- Solidworks (Dassault Systems)

- CAD multi-material printing (GrabCAD)

- SimVascular (open source)

- MeshMixer (AutoDesk Research)